Acid Rain Technology

Case study on Ripsaw - our new product for 2025

In 2018 on a Seattle city bus, I overheard a conversation behind me about an obscure format of music synthesizer products I was obsessed with at the time. I turned around and ended up meeting a guy named Michael who happened to be a brilliant software and electrical engineer also exploring this same odd technological niche. Over the past 6 years the two of us have built a small music tech business together - Acid Rain Technology is focused on a unique sub genre of music synthesizer hardware called "Eurorack modular synthesizers"

Eurorack is a standardized system in which many small businesses like ours design and manufacture compatible "modules" that can be assembled together in a powered case and patched together with cables.

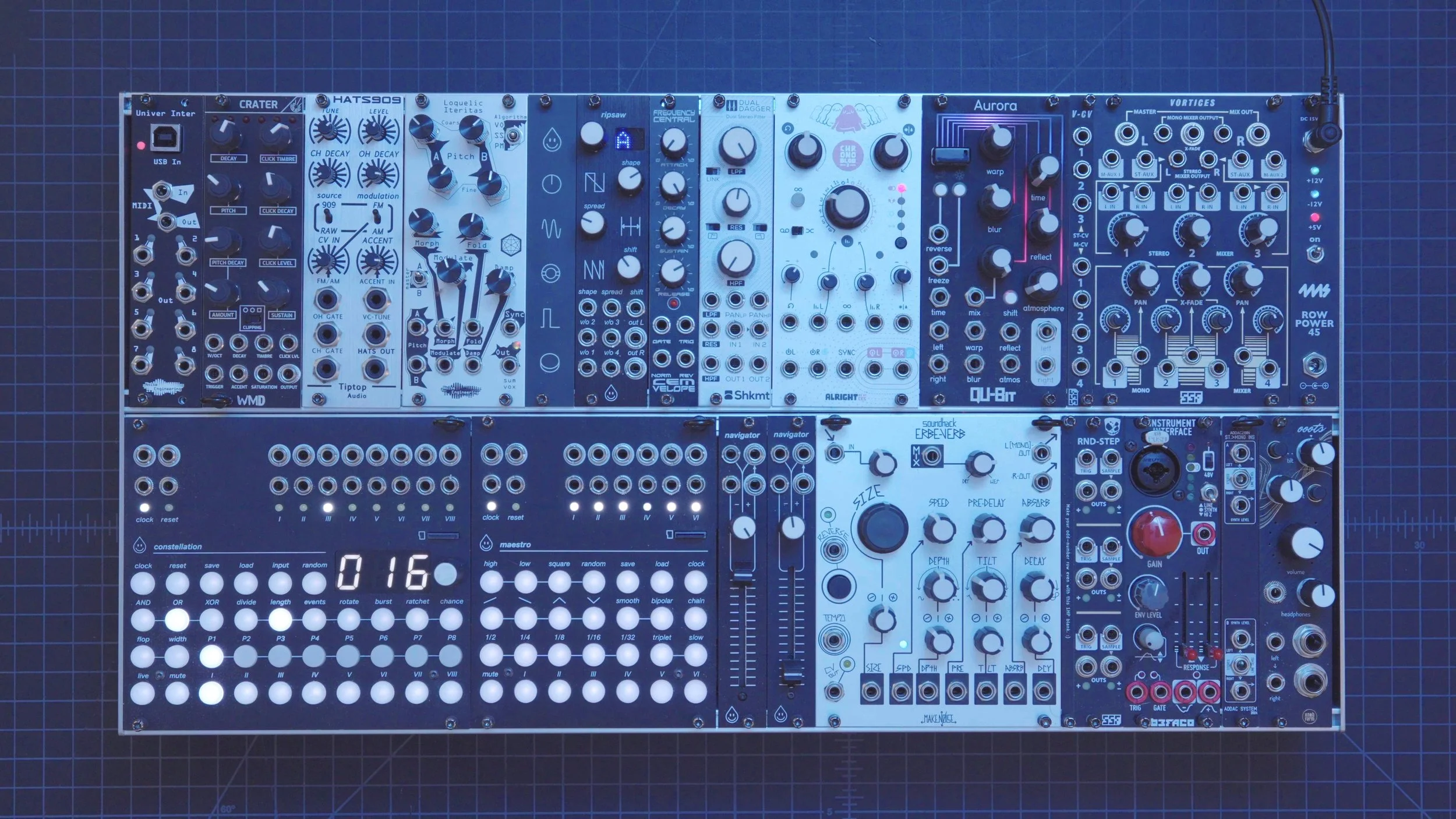

Here is an example of a case filled with several brands of modules including ours:

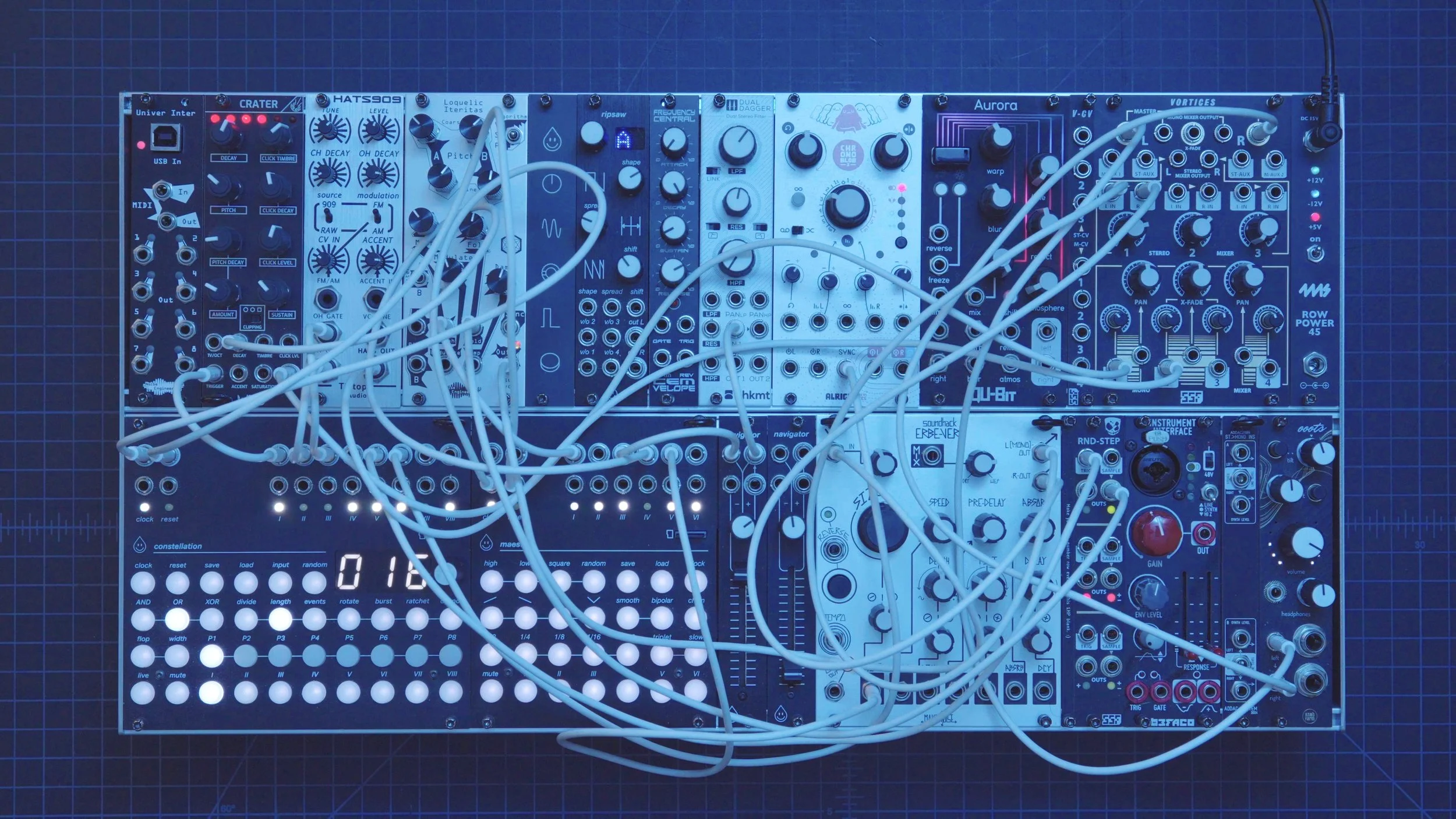

Here it is patched together ready to make sound:

By the end of 2024, Michael and I had designed, manufactured and launched 6 modules to the public:

Acid Rain Technology in 2024

Constellation, our most recent release was physically biggest and highest priced yet

Sales of constellation not up to par with previous successes

Previously successful module Chainsaw had electrical part go out of stock and needed re design to continue production

These circumstances brought us to the idea of re-designing the Chainsaw from the ground up, in a way that would open up the new hardware to be flashed with other software in the future

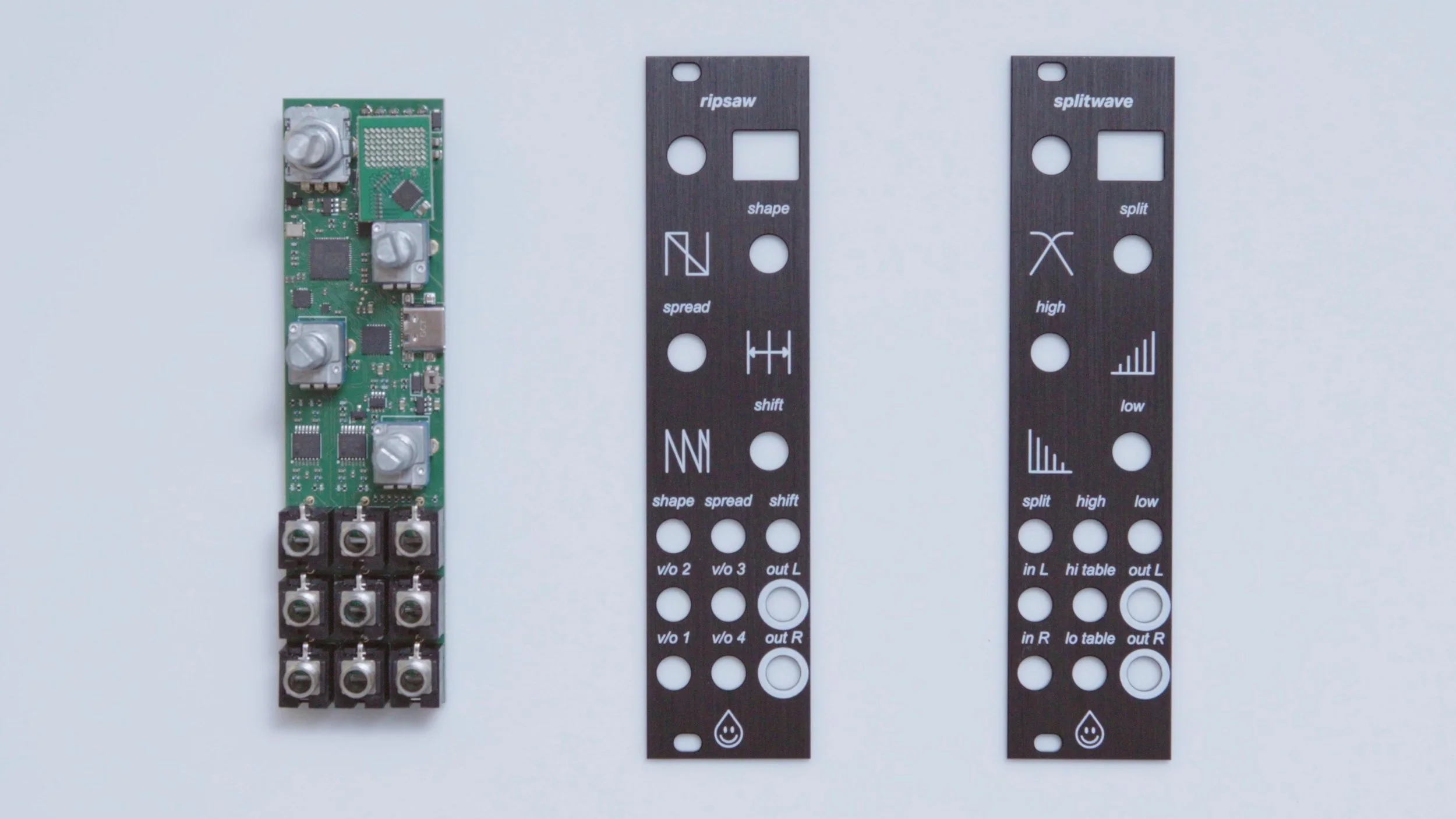

This means the same hardware could be turned into different final products with a simple change of front panel:

Advantages of standardizing internal electronics across multiple SKUs:

a reduction in hardware development time per sku as the hardware is developed once and then utilized over multiple products. As a company we are constrained by developer time with a single software and electrical engineer so dividing Michael's work over as many products as possible adds a lot of value

a reduction in inventory risk per sku as a single production order of the internal electronic assembly can be dynamically allocated across different end product skus as demand dictates - one egg in many baskets

a reduction in QA risk per sku as the internal hardware only needs to be verified and thoroughly tested once. Every new electronic design we create carries risk and requires a lot of time to debug and test to be certain there is no failure in the field after shipping to the end user

Visual Branding through custom illuminated features

Music technology is a space where many people make video content on social media with their equipment. These videos often look something like this:

(image courtesy of Red Means Recording Youtube channel)

We noticed that the LED button grid of the Maestro and Constellation really stood out visually from the sea of other knobs, buttons and cables in our users' video content

These illuminated features serve as a form of branding on our products

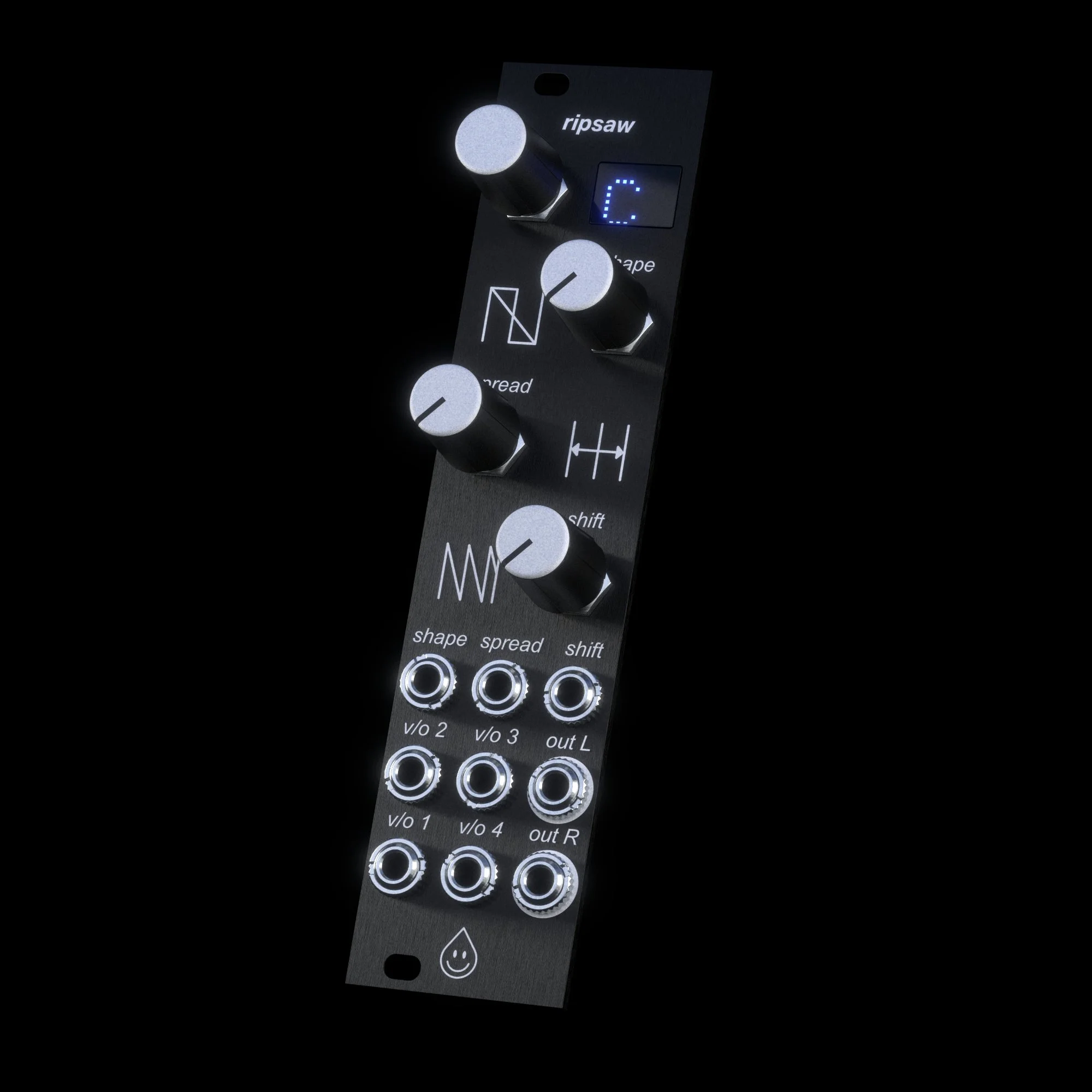

On Ripsaw we decided to develop a custom display unit from 77 minuscule blue LEDs to show letters, numbers and graphic animations that relate to sound parameters of the module

We included this custom illuminated feature to stand out in video content and make the audience wonder what that module with the glowing letter or number might be and encourage them to look further into our product lineup

Thus far in 2025 Ripsaw has been more successful that we hoped! We are restocking components for the second production run and working on new firmware ideas for the hardware platform.